- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

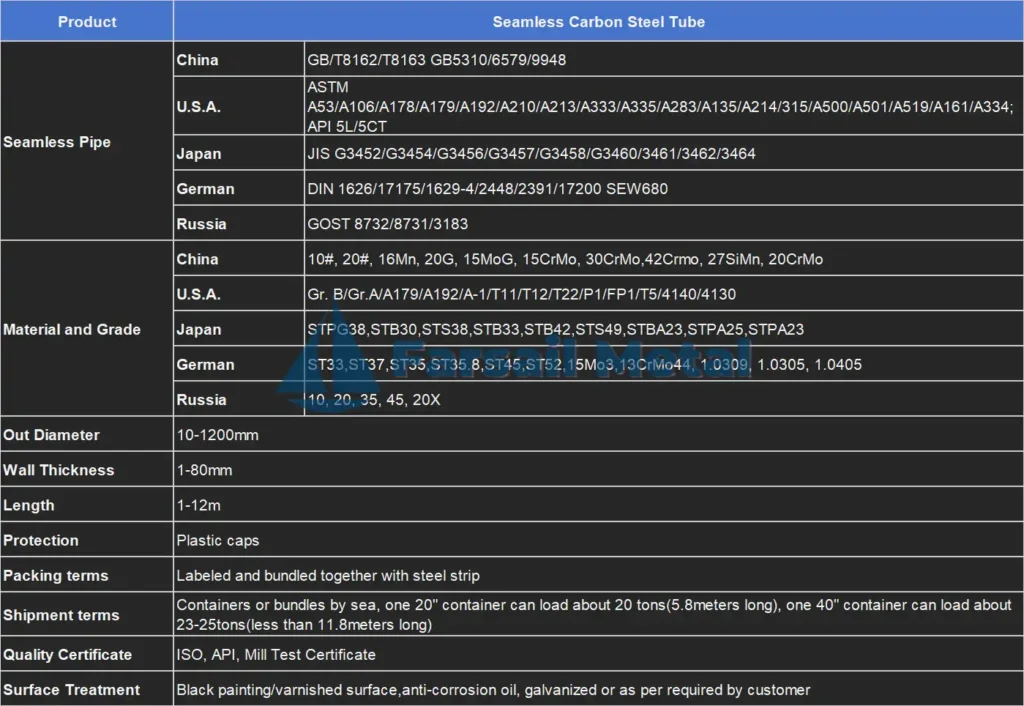

Seamless Pipe, Seamless Carbon Steel Pipe, Carbon Steel Seamless Pipe,Hot Rolled Seamless Steel Pipe, Cold Drawn Seamless Steel Pipe,Cold Rolled Seamless Steel Pipe

Application:

Energy & Petrochemical Industry,Machinery Manufacturing & Precision Components,Construction & Infrastructure,Power Generation Industry,Automotive & Shipbuilding Industry

Specification:

NPS:1/8″~48″;

OD:10.3~1219mm;

WT: SCH 10~160, SCH STD, SCH XS, SCH XXS;

LENGTH: Fixed Length (5.8/6/11.8/12mtr), SRL, DRL

Standard & Grade:

ASTM A53/A106/A179/A192/A210/A213/A295/A333/A335/A519 , API 5L/5CT;

Gr. B/Gr.A/A179/A192/A-1/T11/T12/T22/P1/FP1/T5/4140/4130 ,etc.

GB/T8162/T8163 , GB/T5310/6479/9948;

10#, 20#, 16Mn, 20G, 15MoG, 15CrMo, 30CrMo,42Crmo, 27SiMn, 20CrMo ,etc.

Ends:

Square Ends/Plain Ends (straight cut, saw cut, torch cut), Beveled/Threaded Ends

Surface:

Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing:

Bundled/in Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

| Common standards for seamless carbon steel pipes | Common Grades | Application |

| ASTM A53 | Gr.A, Gr.B | Black and hot-dipped zinc-coated steel pipes welded and seamless |

| ASTM A106 | Gr.A, Gr.B, Gr.C | Seamless carbon steel for high temperature service |

| ASTM SA179 | SA179 | Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

| ASTM SA192 | SA192 | Seamless carbon steel boiler tubes for high pressure |

| ASTM SA210 | Gr.A1 | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A333 | Gr.1(-50℃), Gr.6(-45℃,C-Mn) | seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

| ASTM SA519 | 1020 | Seamless carbon for mechanical tubing |

| API Spec 5CT | H40, J55, K55, L80, N80-1, C95, P110, Q125 | Seamless steel pipe for casing |

| API Spec 5L | PSL1/PSL2 Gr.a,Gr.b, X42/52/60/65/70/80 | Seamless steel pipe for line pipe |

| DIN 17175 | St35.8 | Seamless steel tube for elevated temperture |

| DIN 2391 | St35, St52 | Cold drawn seamless prevision pipe |

| DIN 1629 | St37.0, St44.0, St52.0 | Seamless circular unalloyed steel tubes subject to special requirements |

| GB/T 8162-2018 | 10, 20, 35, 45 | Structural Seamless Steel Pipes |

| GB/T 8163-2018 | 10, 20 | Fluid Transportation Seamless Steel Pipes |

| GB 3087-2008 | 10, 20, 20G | Medium & Low-Pressure Boiler Pipes |

| GB 5310-2017 | 20MnG, 25MnG | High-Pressure Boiler Pipes |

| GB 6479-2013 | 10, 20, 20G | High-Pressure Fertilizer Equipment Seamless Pipes |

| GB 9948-2013 | 10, 20 | Petroleum Cracking Seamless Pipes |

| GB/T 9711-2017 | L245 (Gr.b), L290 (X42), L360 (X52), L415 (X60), L450 (X65), L485 (X70), L555 (X80) | Oil & Gas Pipeline Pipes |

| GB/T 19830-2017 | H40, J55, K55, L80, N80, C95, P110, Q125 | Oil Casing & Tubing |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.