- 818-758-4076

- office@legit.com

- 3146 Koontz Lane, California

Product generic:

Seamless precision Alloy steel tubing, Cold Drawn precision Seamless Steel tubing, Cold Rolled precision Seamless Steel tubing, precision steel tubing, Precision Alloy steel tubing for machinery parts

Application:

Mainly used in industries such as machining, mechanical manufacturing, automotive industry, and hydraulic systems, Precision Machinery and Instruments

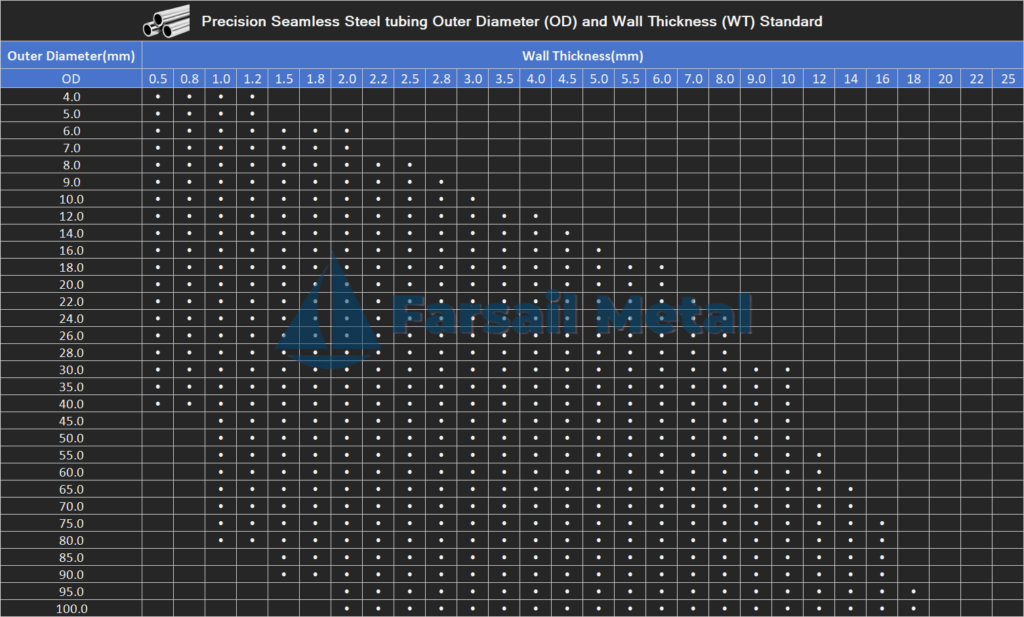

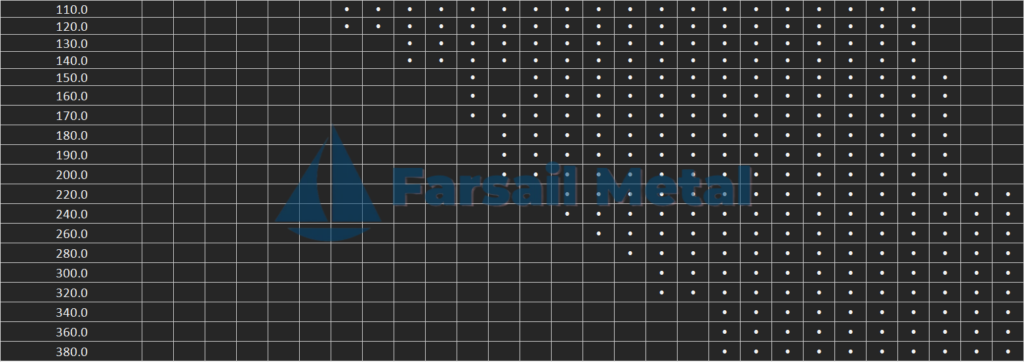

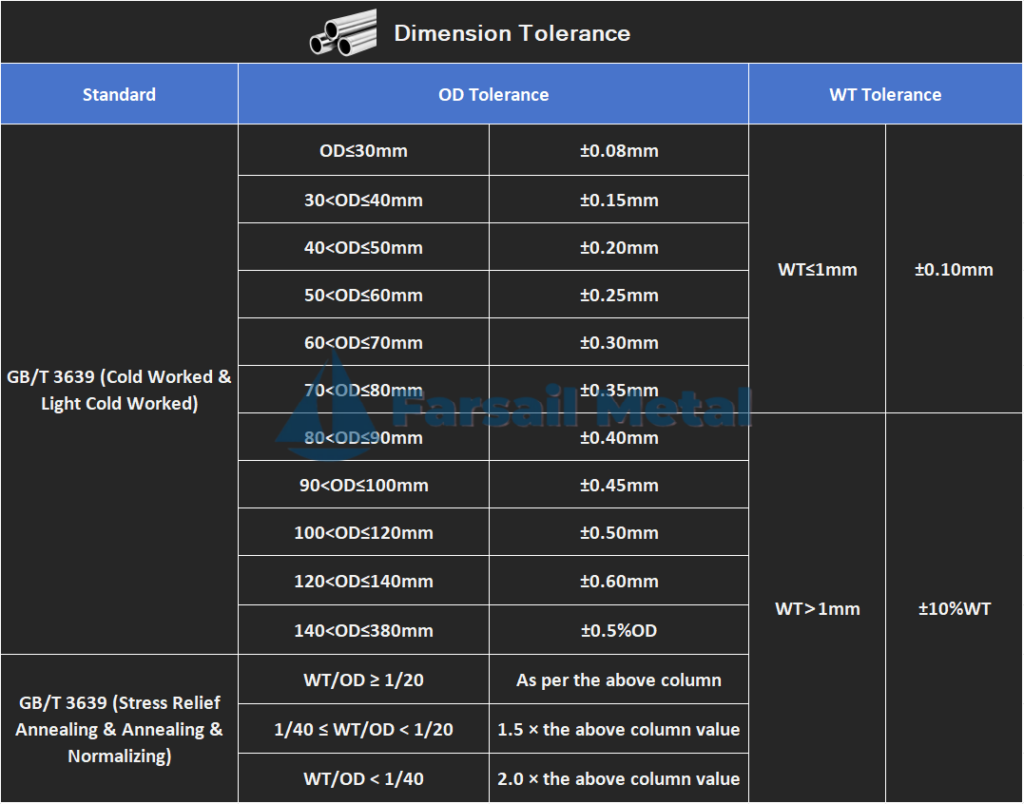

Specification:

OD: 4~380 mm

WT: 0.5~25 mm

LENGTH: Fixed Length (5.8/6/11.8/12mtr),Specifed by purchaser

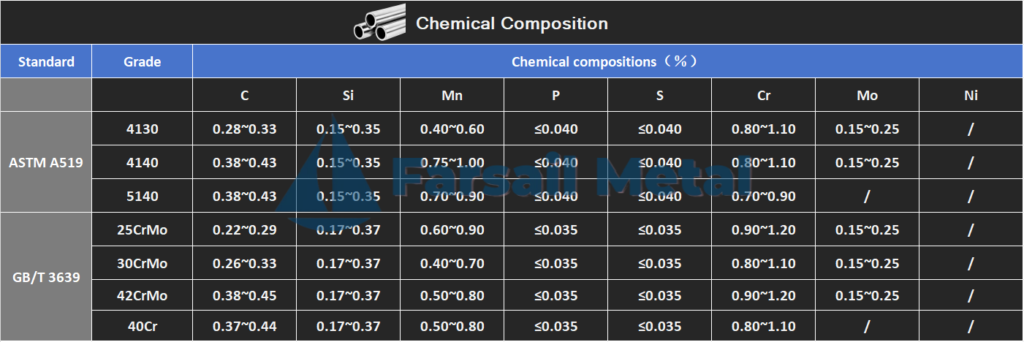

Standard & Grade:

ASTM A519:4130,4140,5140;

EN 10305-1:34CrMo4,42CrMo4,42Cr4;

GB/T 3639:30CrMo,42CrMo,40Cr;

Ends:

Plain Ends,Chamfered Ends

Surface:

Bare, Lightly Oiled, Painting, Zinc/Anti-corrosive Coating

Packing:

Bundled/in Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

| Common standards for seamless alloy steel pipes | Common Grades | Application |

| ASTM SA210 | Gr.C | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A213 | T5, T11, T22, T91, T92 | Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

| ASTM A333 | Gr.3(-100℃,3.5Ni) , Gr.9(-195℃,9Ni ) | seamless and welded carbon and alloy steel pipe intended for use at low temperatures |

| ASTM A335 | P5, P11, P22, P91, P92 | Seamless ferritic alloy-steel pipe for high-temperature service |

| ASTM SA519 | 4130, 4140 | Seamless carbon for mechanical tubing |

| API Spec 5CT | L80-13Cr | Seamless steel pipe for casing |

| ASTM A295 | 52100 | High-Carbon Anti-Friction Bearing Steel |

| DIN 17175 | 15Mo3, 13CrMo4-5 | Seamless steel tube for elevated temperture |

| EN ISO 683-17 | 100Cr6 | Ball and roller bearing steels |

| GB/T 8162-2018 | Q345, Q390 | Structural Seamless Steel Pipes |

| GB/T 8163-2018 | Q345 | Fluid Transportation Seamless Steel Pipes |

| GB 5310-2017 | 15CrMoG, 12Cr1MoVG , T91/P91 (10Cr9Mo1VNb) ,T92/P92 (10Cr9MoW2VNb) | High-Pressure Boiler Pipes |

| GB 6479-2013 | 15CrMo, 12Cr2Mo | High-Pressure Fertilizer Equipment Seamless Pipes |

| GB 9948-2013 | 12CrMo, 15CrMo, 1Cr5Mo | Petroleum Cracking Seamless Pipes |

| GB/T 18984-2016 | 09Mn2V, 16MnDG | Low-Temperature Service Pipes |

| GB/T 17396-2022 | 27SiMn | Hydraulic Support Pipes |

| GB/T 33959-2017 | L80-13Cr | Petroleum and Natural Gas Industry – Corrosion-Resistant Alloy Casing and Tubing |

| GB/T 18254-2016 | GCr15 | High-carbon Chromium Bearing Steel |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.