- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

High-Pressure Fertilizer Equipment Alloy Steel Pipe,Seamless Steel Pipe for High – Pressure Fertilizer Equipment,Alloy Steel Pipe for Chemical Fertilizer Industry,High – Pressure Chemical Fertilizer Pipe

Application:

For transporting corrosive media (e.g., ammonia, hydrogen, sulfur compounds) and high-temperature gases,Used in Fertilizer Production Industry,Chemical Industry

Specification:

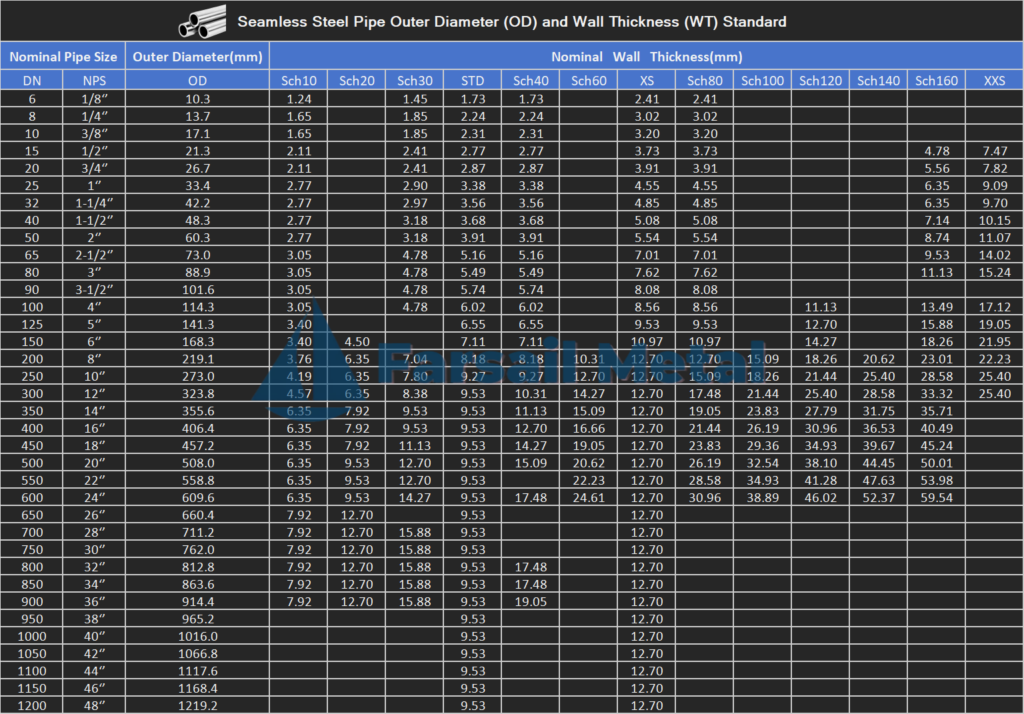

OD:1/8″~48″(10.3~1219mm)

WT: SCH 10~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr),SRL, DRL

Standard & Grade:

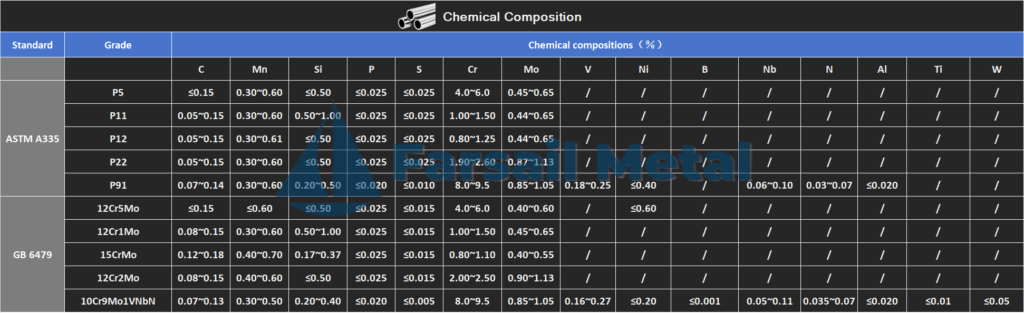

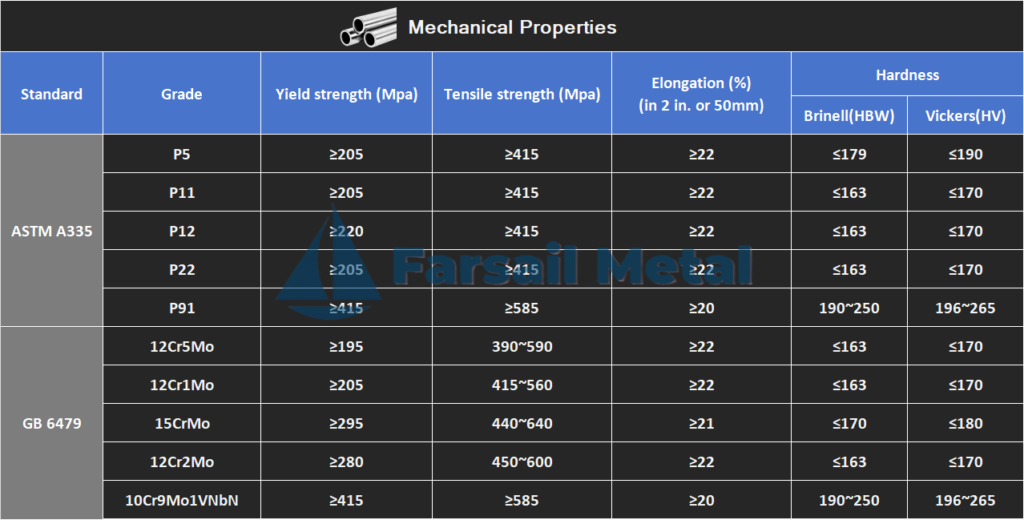

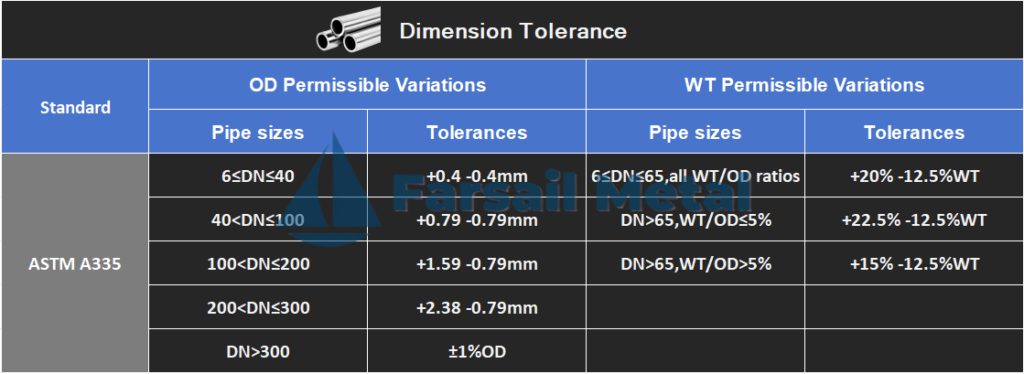

ASTM A335:P5,P11,P22,P91;

EN 10216-2:10CrMo5-5,13CrMo4-5,10CrMo9-10,X10CrMoVNb9-1;

GB 6479:12Cr5Mo,15CrMo,12Cr2Mo,10Cr9Mo1VNbN.

Ends:

Plain End, Beveled End

Surface:

Bare, Black/Varnish Painting, Hot galvanized, Anti-corrosive Coating,

according to your requirements

Packing:

Bundled/in Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

| Common standards for seamless alloy steel pipes | Common Grades | Application |

| ASTM SA210 | Gr.C | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A213 | T5, T11, T22, T91, T92 | Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

| ASTM A333 | Gr.3(-100℃,3.5Ni) , Gr.9(-195℃,9Ni ) | seamless and welded carbon and alloy steel pipe intended for use at low temperatures |

| ASTM A335 | P5, P11, P22, P91, P92 | Seamless ferritic alloy-steel pipe for high-temperature service |

| ASTM SA519 | 4130, 4140 | Seamless carbon for mechanical tubing |

| API Spec 5CT | L80-13Cr | Seamless steel pipe for casing |

| ASTM A295 | 52100 | High-Carbon Anti-Friction Bearing Steel |

| DIN 17175 | 15Mo3, 13CrMo4-5 | Seamless steel tube for elevated temperture |

| EN ISO 683-17 | 100Cr6 | Ball and roller bearing steels |

| GB/T 8162-2018 | Q345, Q390 | Structural Seamless Steel Pipes |

| GB/T 8163-2018 | Q345 | Fluid Transportation Seamless Steel Pipes |

| GB 5310-2017 | 15CrMoG, 12Cr1MoVG , T91/P91 (10Cr9Mo1VNb) ,T92/P92 (10Cr9MoW2VNb) | High-Pressure Boiler Pipes |

| GB 6479-2013 | 15CrMo, 12Cr2Mo | High-Pressure Fertilizer Equipment Seamless Pipes |

| GB 9948-2013 | 12CrMo, 15CrMo, 1Cr5Mo | Petroleum Cracking Seamless Pipes |

| GB/T 18984-2016 | 09Mn2V, 16MnDG | Low-Temperature Service Pipes |

| GB/T 17396-2022 | 27SiMn | Hydraulic Support Pipes |

| GB/T 33959-2017 | L80-13Cr | Petroleum and Natural Gas Industry – Corrosion-Resistant Alloy Casing and Tubing |

| GB/T 18254-2016 | GCr15 | High-carbon Chromium Bearing Steel |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.