- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

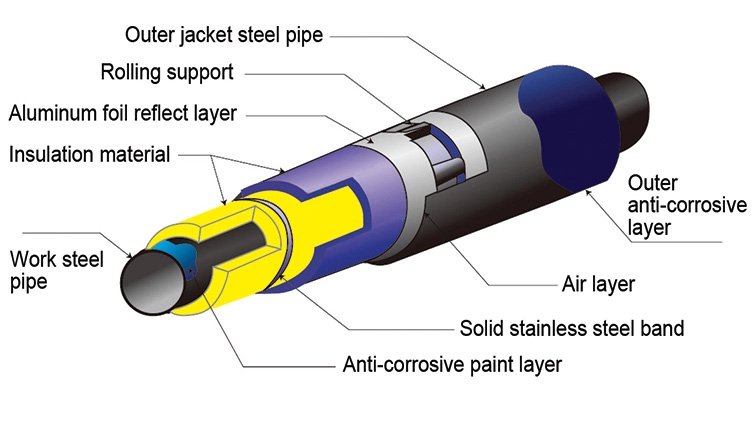

Product generic:

Steel Jacketed Steel Insulated Pipe,Steel Cased Insulated Pipe,Steam Insulated Steel Pipe,Steel Jacketed Insulation Tube,Steel Jacketed Steam Pipe

Application:

Urban district heating networks,Steam transmission and thermal cycle systems,Transportation of high-temperature process media,Thermal energy transmission

Specification:

OD:10.3~3048mm

WT: 0.5~80mm

LENGTH: Fixed Length (5.8/6/11.8/12mtr),SRL, DRL

Standard & Grade:

ASTM A53: Grade A、B,

ASTM A106: Grade A、B、C;

EN 10255: S195T、S235JRH、S275JRH、S355JRH;

GB/T 13793: Q195、Q215A/B、Q235A/B、Q355B、Q390B,

GB/T 3091: Q215A/B、Q235A/B、Q355B,

GB/T 8163:10#,20#,Q355,Q420;

Ends:

Plain Ends,Beveled Ends,Threaded Ends

Surface:

Outer Jacket:PE/3LPE/FBE/ECTP Coating Steel Pipe

Packing:

Bundled/in Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Common standards for Insulated Steel Pipes | Common Grades | Main Application |

ASTM A106/A106M-2021 | Gr.A, Gr.B, Gr.C | Seamless carbon steel pipe for high-temperature service.(Insulated main steam pipelines in thermal power plants, High-temperature industrial pipeline,etc.) |

ANSI/ASME B36.10M-2018 | Gr.a,Gr.b, X42/52/60/65/70/80 | Welded and seamless wrought steel pipe.(Insulated pipeline for low-temperature hot water/steam,Central heating pipeline, Long-distance heat-insulated pipeline for oil and gas transportation,Heat tracing system for thermal pipelines,etc.) |

EN 253:2019 | S235JRH, S355J2H, P235GH | District heating pipes – Pre-insulated bonded pipe systems.(The main network of urban central heating, the geothermal pipeline for snow melting, the high-pressure steam pipeline,etc) |

GB/T 29047-2012 | Q235B, Q345B, L245 (Gr.b), L290 (X42), L360 (X52), L415 (X60), L450 (X65), L485 (X70), L555 (X80) | Prefabricated polyurethane foam-insulated steel pipes with polyethylene jacket for underground heating.(Urban district heating networks , cooling pipe systems) |

GB/T 50484-2019 | 20#,Q345B,304,316 | Insulation (hot/cold) works in petrochemical plants. (Insulated pipeline for high-temperature steam, buried thermal anti-corrosion and insulated pipeline network, low-temperature cold-insulated pipeline, etc.) |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.