- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

Stainless Steel Coil Tube,Stainless Steel Coiled Tubing

Application:

Chemical Processing,Food & Beverage,Pharmaceutical & Medical,HVAC & Refrigeration

Specification:

OD: 6~50 mm

WT: 0.5~4.57 mm

LENGTH: 30m/coil,50m/coil,100m/coil,Specifed by purchaser

Standard & Grade:

ASTM A269,ASTM A213,ASTM A249;

EN 10216-5,EN 10217-7;

GB/T 14976,GB/T 12771,GB/T 13296.

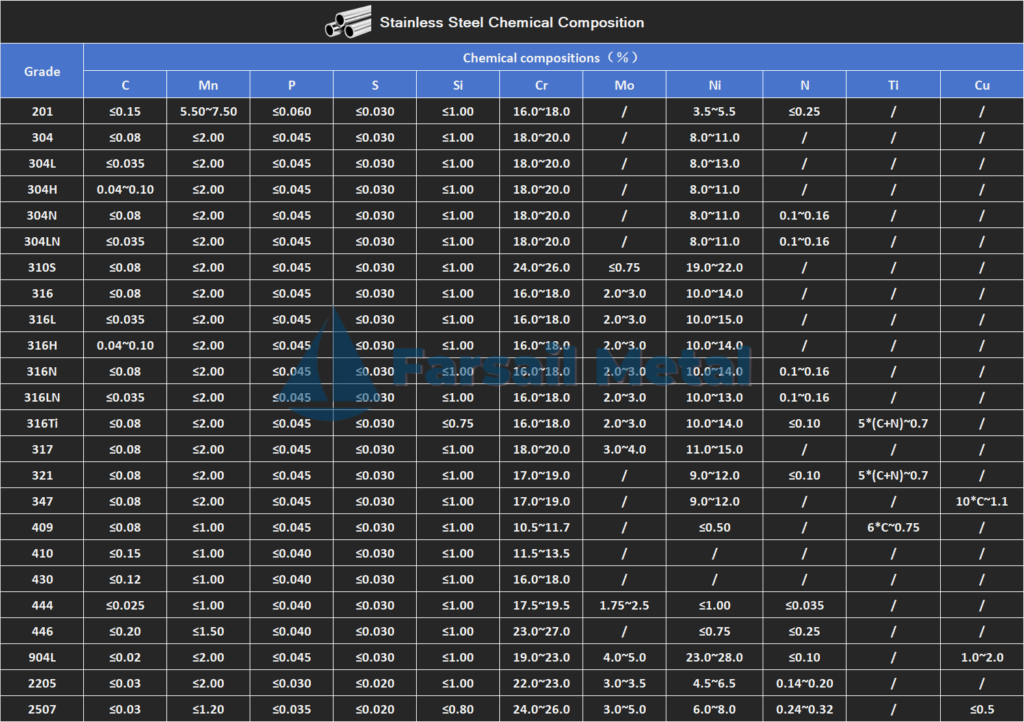

304/304L,316/316L,321;

1.4301/1.4306,1.4401/1.4404,1.4541.

Ends:

Plain Ends

Surface:

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirro

Packing:

Stretch film wrapped, bundled, plastic caps sealed at both ends

| Common Standards for Stainless Steel Pipes | Common Grades | Applications |

| ASTM A213 | TP304H, TP316H, TP321H, TP347H | Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes .(High-pressure boiler tubes,Superheater tubes,Heat-exchanger tubes,Nuclear power plant piping) |

| ASTM A312 | TP304/304L, TP316/316L, TP321 | Seamless and Welded Austenitic Stainless Steel Pipes.(Chemical piping, food industry, cryogenic equipment, etc. ) |

| ASTM A269 | TP304/304L, TP316/316L, TP317L, TP904L | Seamless and Welded Austenitic Stainless Steel Tubing for General Service.(Fluid handling systems,Medical devices,Pharmaceutical industry) |

| ASTM A268 | TP409,TP430, TP446, TP410,TP420 | Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service.(Automotive Exhaust,Household Appliances,Industrial Equipment) |

| ASTM A270 | TP304/304L, TP316/316L | Seamless and Welded Austenitic Stainless Steel Sanitary Tubing.(Food & Dairy Processing,Pharmaceutical & Biotech,Beverage Handling) |

| ASTM A249 | TP304/304H、TP316/316L、TP321,TP347 | Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes.(Boilers,Superheaters,Heat exchangers,Condensers) |

| ASTM A376 | TP304H、TP316H、TP321H | Seamless Austenitic Stainless Steel Pipes for High-Temperature Service.(High-temperature steam lines,Nuclear primary steam systems,Petroleum cracking units) |

| ASTM A632 | TP304, TP316L, TP321,TP317L | Seamless and Welded Austenitic Stainless Steel Tubing .(Small-Diameter) for General Service(outside diameter ≤2 inches,non-pressure applications) |

| ASTM A789 | TP2205、TP2507 | Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service.( Subsea pipelines,Desalination,Desalination,etc.) |

| ASTM A1016/A1016M | General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes | |

| DIN EN 10216-5 | 1.4301(304), 1.4307(304L),1.4401(316), 1.4404(316L),1.4541(321),1.4462(2205) | Seamless Steel Tubes for Pressure Purposes.(Power plant boilers,Bioreactors,Dairy processing,Desalination plants) |

| DIN EN 10217-7 | 1.4301(304),1.4307(304L), 1.4404(316L),1.4571 (316Ti) | Welded Steel Tubes for Pressure Purposes.(Pickling line pipes,Heat exchanger bundles, etc. ) |

| DIN EN 10297-2 | 1.4301(304), 1.4401(316), 1.4021(420),1.4539(904L) | Seamless Steel Tubes for Mechanical and General Engineering Purposes.(Drive shafts,Hydraulic cylinders,Medical instruments) |

| DIN EN 10305-1 | 1.4306(304L), 1.4406(316L) | Steel Tubes for Precision Application.(Primarily for mechanical engineering applications) |

| GB/T 14976 | 06Cr19Ni10(304), 022Cr19Ni10(304L),06Cr17Ni12Mo2(316),022Cr17Ni12Mo2(316L),06Cr18Ni11Ti(321) | Seamless Stainless Steel Pipes for Fluid Transport.(Corrosive fluid lines,Purified water systems) |

| GB/T 13296 | 07Cr19Ni10(304H), 07Cr17Ni12Mo2(316H),06Cr18Ni11Ti(321),022Cr25Ni7Mo4N (2507) | Seamless Stainless Steel Tubes for Boilers/Heat Exchangers.(Supercritical boiler superheater tubes,Steam generator tubes,Molten salt pipes for CSP plants) |

| GB/T 12771 | 06Cr19Ni10(304), 022Cr19Ni10(304L),06Cr17Ni12Mo2(316),022Cr17Ni12Mo2(316L),06Cr18Ni11Ti(321) | Welded Stainless Steel Pipes for Fluid Transport.(Water Treatment,Food,Chemical) |

| GB/T 21833 | 022Cr23Ni5Mo3N(2205), 022Cr25Ni7Mo4N(2507) | Duplex Stainless Steel Seamless Pipes.(Marine engineering, seawater desalination, petroleum, chemical industry, nuclear power) |

| GB/T 24593 | 07Cr19Ni10 (304H),022Cr17Ni12Mo2 (316L) | Welded Stainless Steel Tubes for Boilers and Heat Exchangers.(Supercritical boiler,Nuclear power,High-temperature heat exchanger) |

| GB/T 30066 | 022Cr11Ti(409),10Cr17(430),10Cr25(446) | Ferritic stainless steel welded tubes for heat exchangers and condensers.(Automotive industry, home appliances and architectural decoration, industrial equipment) |

| GB 4806.9 | 06Cr19Ni10(304), 022Cr19Ni10(304L),06Cr17Ni12Mo2(316),022Cr17Ni12Mo2(316L) | Metal Materials and Articles for Food Contact.(Food and beverage processing pipelines,etc. ) |

| GB/T 29038 | 06Cr19Ni10(304), 022Cr19Ni10(304L),06Cr17Ni12Mo2(316),022Cr17Ni12Mo2(316L) | Technical specification for thin-wall stainless steel pipes.(Building water supply,Purified water systems,etc.) |

| YB/T 5363 | 12Cr17Mn6Ni5N(201/201Cu),06Cr19Ni10(304) | Decorative welded stainless steel pipes. (Architecture,Household,Transport) |

| GB/T 14975 | 12Cr13(410),20Cr13(420),68Cr17(440) | Stainless steel seamless tubes/pipes for structural purposes.(tools, machinery and bearings) |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.