- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

Casing Pipe, Steel Casing Pipe, Oil Well Casing, OCTG Casing & Tubing, Seamless Casing, Oil Casing, API Casing, Well Casing, Casing

Application:

Used for oil casing and tubing in oil wells as well as sidewall

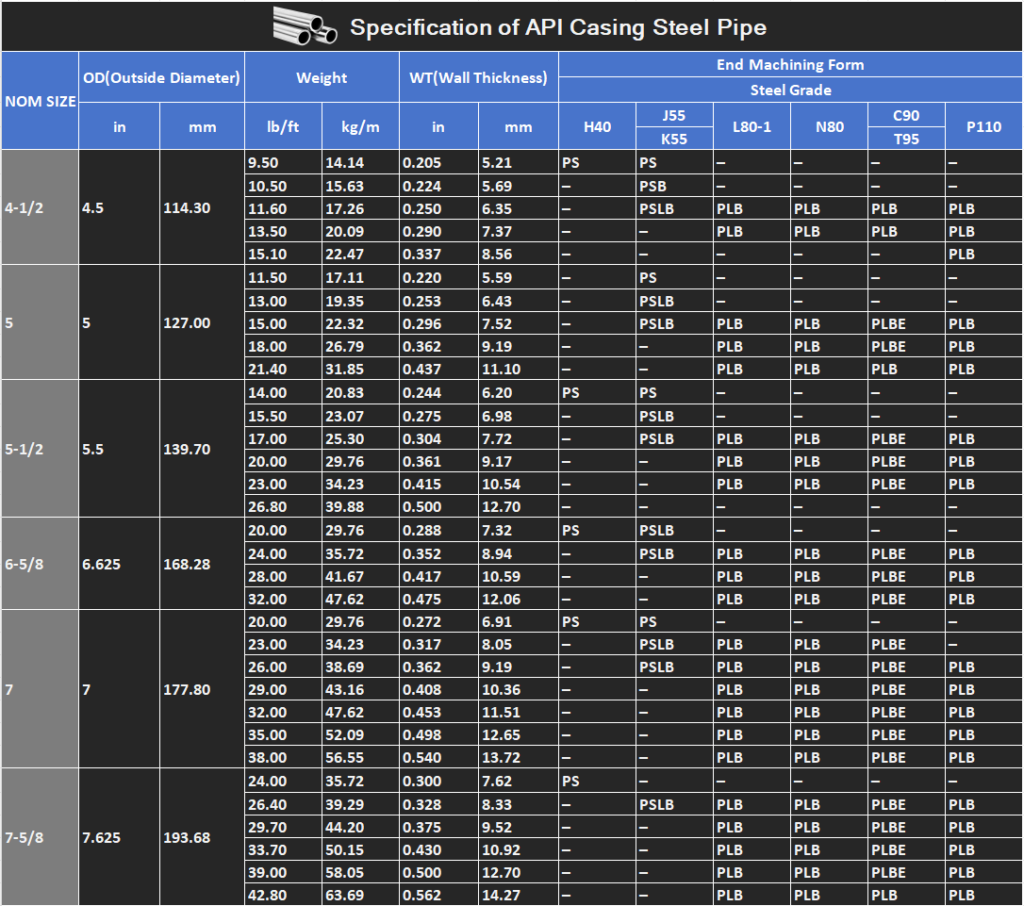

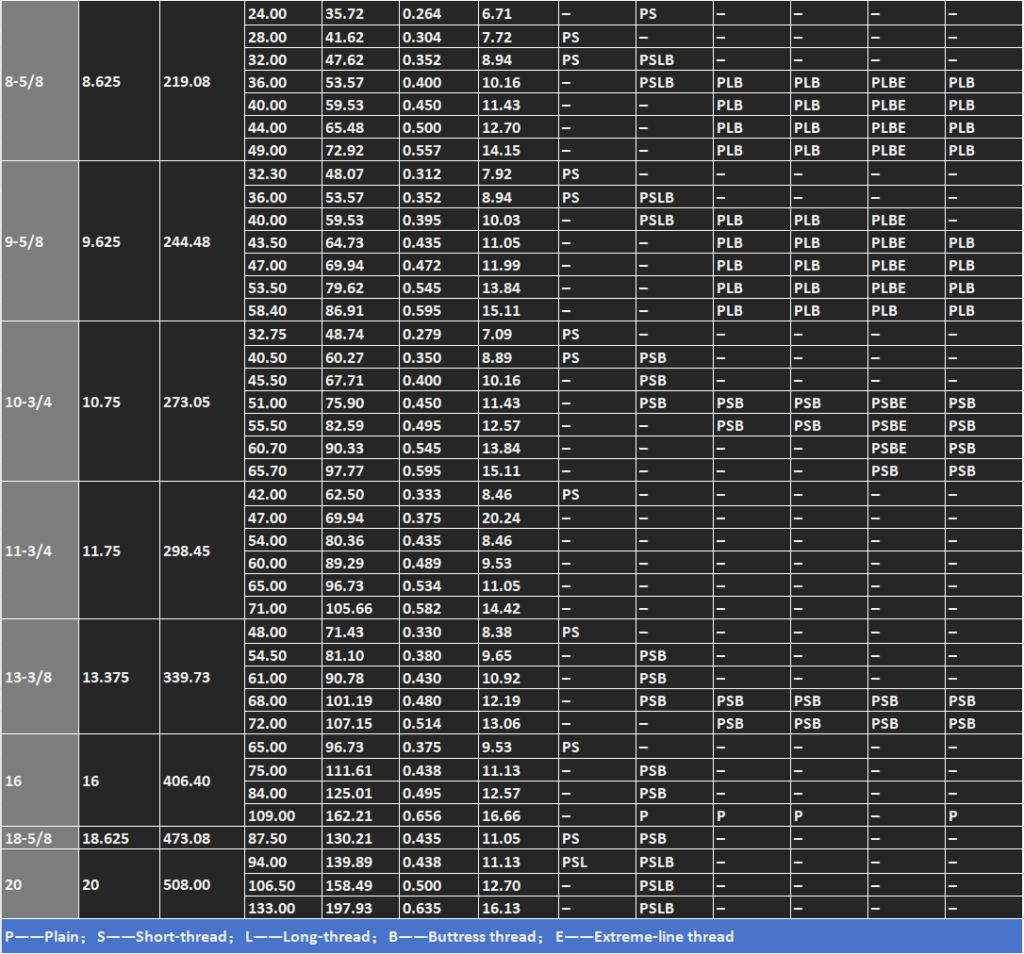

Specification:

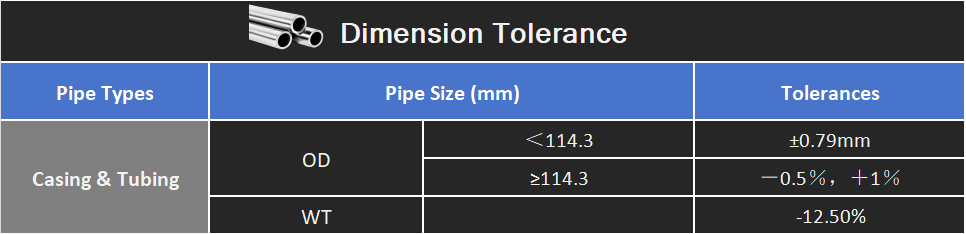

OD:4 1/2″~20″(114.3~508mm);

WT: 5.21~16.13mm

LENGTH: R1(4.88~7.62m);R2(7.62~10.36m);R3(10.36~14.63m)

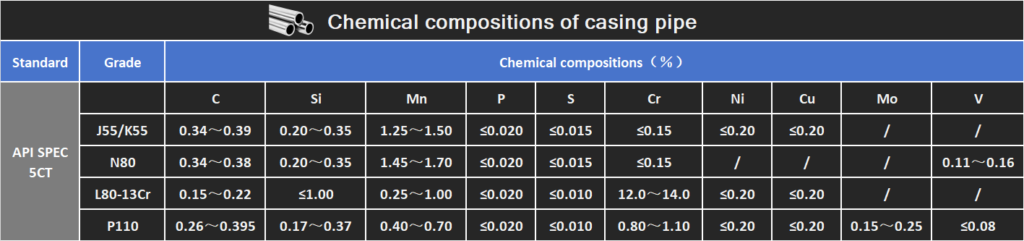

Standard & Grade:

API 5CT PSL1/PSL2 J55,K55,N80-1,N80-Q,L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125

Thread:

NUE, EUE, STC, LTC, BTC,Hydrill CS/Tenaris XC/VAM

Surface:

Anti-corrosion&water Based Paint

Oil casing is a critical tubular product used in oil and gas well drilling and completion. Its primary functions include supporting the wellbore, isolating formations with different pressures, preventing wellbore collapse, and ensuring safe hydrocarbon production.

Wellbore Support: Prevents formation collapse and maintains well stability; Zonal Isolation: Seals off different pressure zones (e.g., water, gas, oil layers); Protection for Tubing: Provides a secure conduit for production tubing; Well Control: Prevents blowouts in high-pressure reservoirs.

API 5CT (American Petroleum Institute); ISO 11960 (International Organization for Standardization); GB/T 19830 (Chinese National Standard).

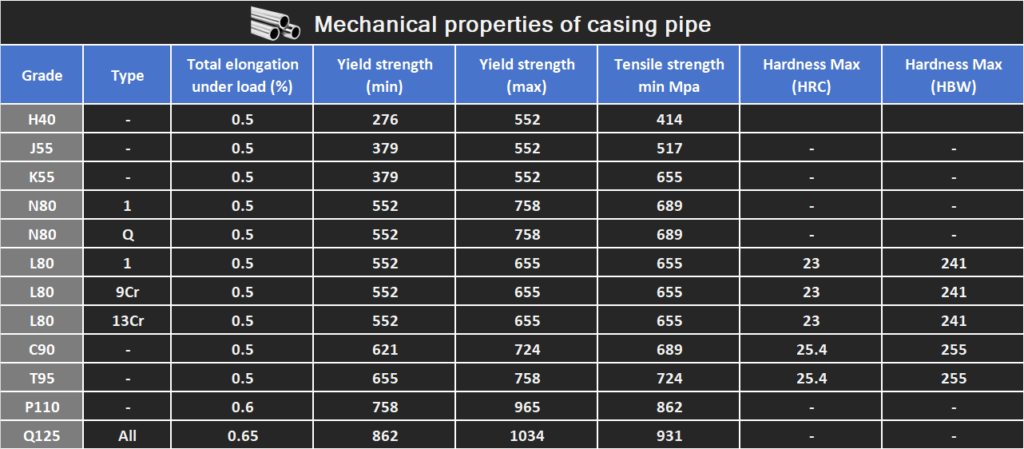

H40, J55, K55 : Standard wells (low corrosion); N80, L80, C90 : Medium-depth wells (moderate corrosion); P110, Q125 : Deep/ultra-deep wells (high collapse resistance); L80-13Cr : High CO₂/H₂S corrosive environments.

Hot Rolling; Cold Rolling; Threading: API standard (NUE, EUE, STC, LTC, BTC) or premium connections (Hydril CS,Tenaris XC)

| Common standards for seamless carbon steel pipes | Common Grades | Application |

| ASTM A53 | Gr.A, Gr.B | Black and hot-dipped zinc-coated steel pipes welded and seamless |

| ASTM A106 | Gr.A, Gr.B, Gr.C | Seamless carbon steel for high temperature service |

| ASTM SA179 | SA179 | Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

| ASTM SA192 | SA192 | Seamless carbon steel boiler tubes for high pressure |

| ASTM SA210 | Gr.A1 | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A333 | Gr.1(-50℃), Gr.6(-45℃,C-Mn) | seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

| ASTM SA519 | 1020 | Seamless carbon for mechanical tubing |

| API Spec 5CT | H40, J55, K55, L80, N80-1, C95, P110, Q125 | Seamless steel pipe for casing |

| API Spec 5L | PSL1/PSL2 Gr.a,Gr.b, X42/52/60/65/70/80 | Seamless steel pipe for line pipe |

| DIN 17175 | St35.8 | Seamless steel tube for elevated temperture |

| DIN 2391 | St35, St52 | Cold drawn seamless prevision pipe |

| DIN 1629 | St37.0, St44.0, St52.0 | Seamless circular unalloyed steel tubes subject to special requirements |

| GB/T 8162-2018 | 10, 20, 35, 45 | Structural Seamless Steel Pipes |

| GB/T 8163-2018 | 10, 20 | Fluid Transportation Seamless Steel Pipes |

| GB 3087-2008 | 10, 20, 20G | Medium & Low-Pressure Boiler Pipes |

| GB 5310-2017 | 20MnG, 25MnG | High-Pressure Boiler Pipes |

| GB 6479-2013 | 10, 20, 20G | High-Pressure Fertilizer Equipment Seamless Pipes |

| GB 9948-2013 | 10, 20 | Petroleum Cracking Seamless Pipes |

| GB/T 9711-2017 | L245 (Gr.b), L290 (X42), L360 (X52), L415 (X60), L450 (X65), L485 (X70), L555 (X80) | Oil & Gas Pipeline Pipes |

| GB/T 19830-2017 | H40, J55, K55, L80, N80, C95, P110, Q125 | Oil Casing & Tubing |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.