- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

Line Pipe, API Line Pipe, Seamless Line Pipe, Carbon Steel Line Pipe,Seamless Pipe, Seamless Carbon steel Pipe, Carbon steel Seamless Pipe, Hot Rolled Seamless steel Pipe, Cold Drawn Seamless Steel Pipe, Cold Rolled Seamless Steel Pipe

Application:

For Transportation in petroleum and natural gas industries

Specification:

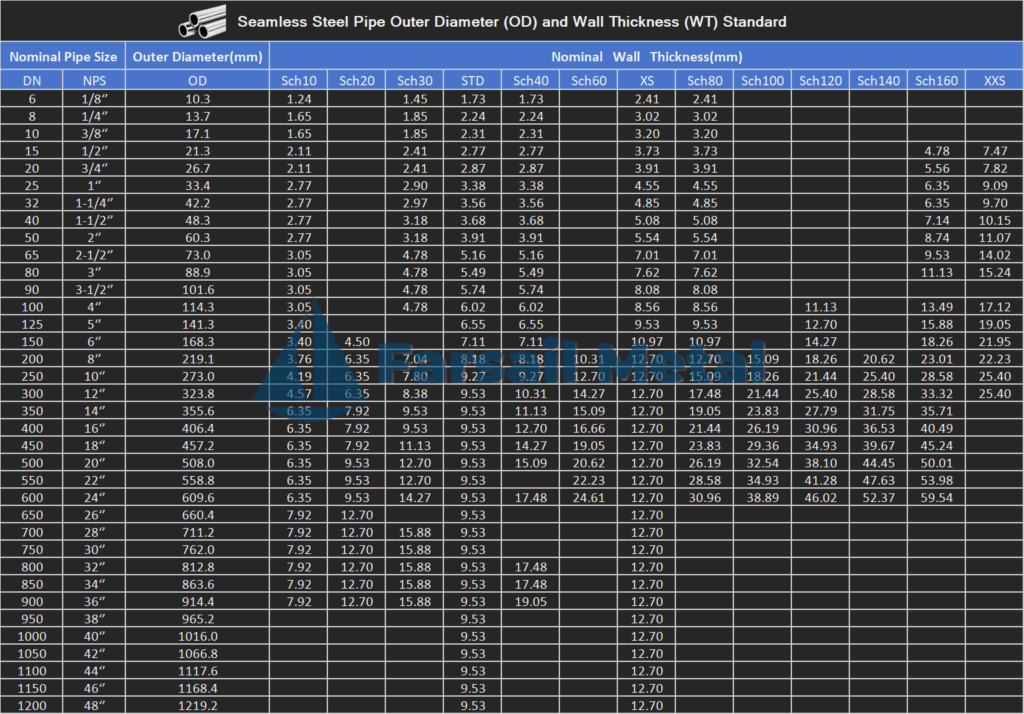

NPS:1/8″~48″

OD:10.3~1219mm

WT: SCH 10~ 160, SCH STD, SCH XS, SCH XXS

LENGTH: Fixed Length (5.8/6/11.8/12mtr),SRL, DRL

Standard & Grade:

ISO 3183:2019;API 5L;EN 10208-1;GB/T 9711

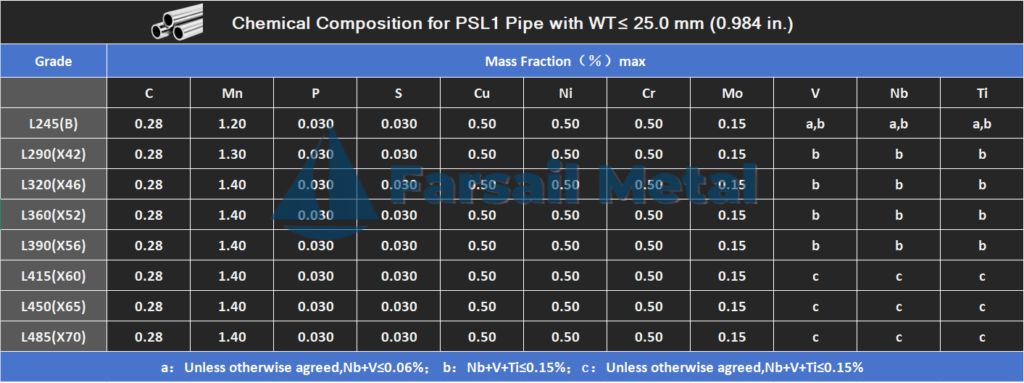

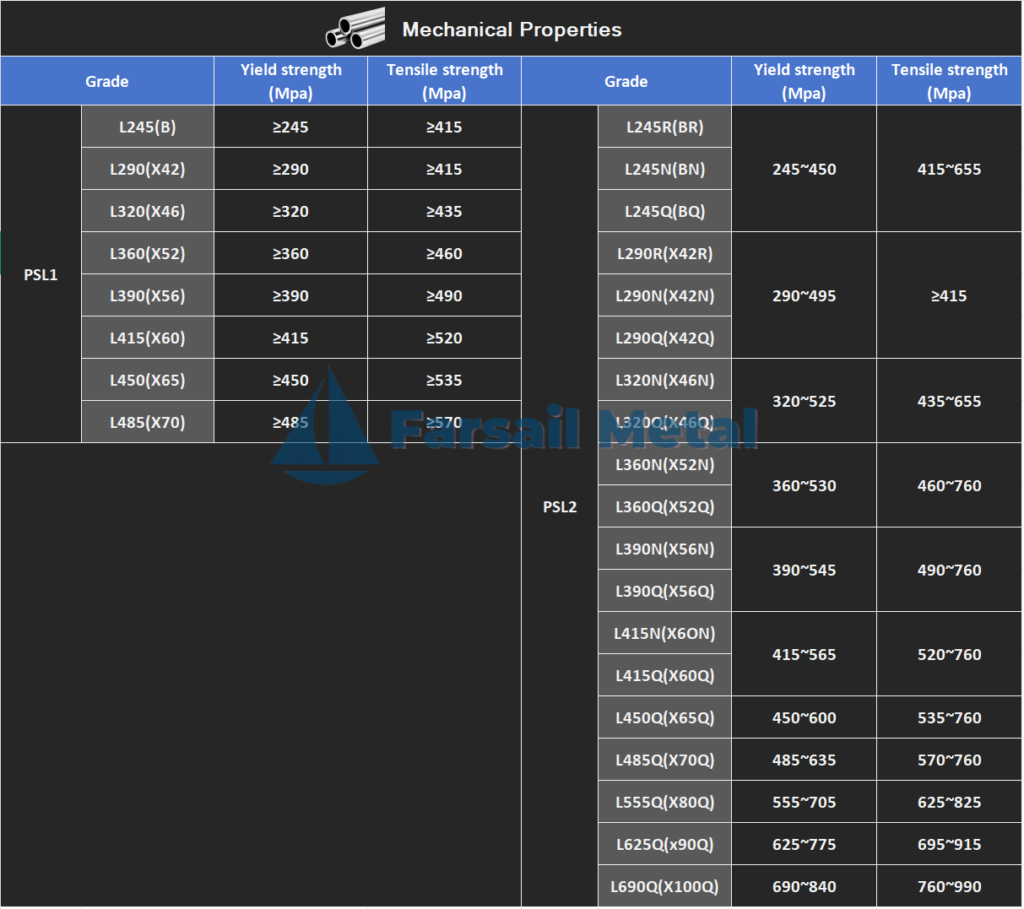

PSL1:L245(B),L290(X42),L320(X46),L360(X52),L390(X56),L415(X60),

L450(X65),L485(X70);

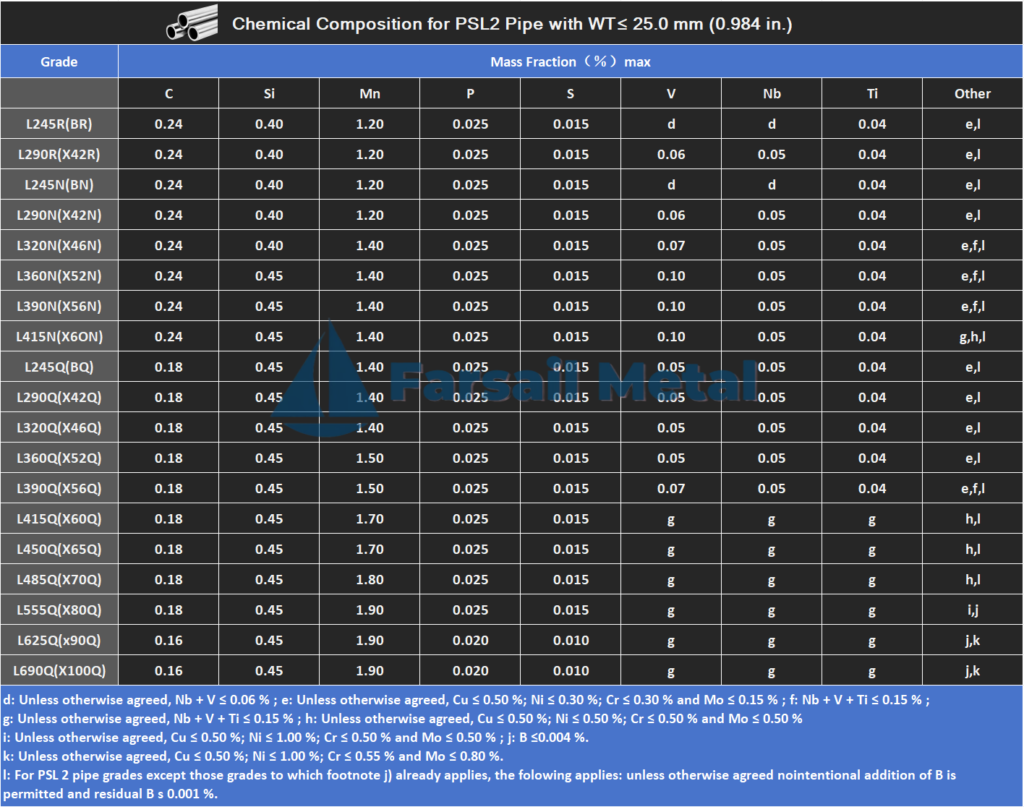

PSL2:L245R(BR),L290R(X42R),L245N(BN),L290N(X42N),L320N(X46N),

L360N(X52N),L390N(X56N),L415N(X60N),L245Q(BQ),L290Q(X42Q),

L320Q(X46Q),L360Q(X52Q),L390Q(X56Q),L415Q(X60Q),L450Q(X65Q),

L485Q(X70Q),L555Q(X80Q),L625Q(X90Q),L690Q(X100Q);

Ends:

Plain End, Beveled End, belled end, Threaded End,Coupling

Surface:

Epoxy Coating, Colour Paint Coating, 3LPE Coating

Packing:

Loose,Bundle,Plastic Cloth Wraps,Plastic End Caps,Beveled Protector

| Common standards for seamless carbon steel pipes | Common Grades | Application |

| ASTM A53 | Gr.A, Gr.B | Black and hot-dipped zinc-coated steel pipes welded and seamless |

| ASTM A106 | Gr.A, Gr.B, Gr.C | Seamless carbon steel for high temperature service |

| ASTM SA179 | SA179 | Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

| ASTM SA192 | SA192 | Seamless carbon steel boiler tubes for high pressure |

| ASTM SA210 | Gr.A1 | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A333 | Gr.1(-50℃), Gr.6(-45℃,C-Mn) | seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

| ASTM SA519 | 1020 | Seamless carbon for mechanical tubing |

| API Spec 5CT | H40, J55, K55, L80, N80-1, C95, P110, Q125 | Seamless steel pipe for casing |

| API Spec 5L | PSL1/PSL2 Gr.a,Gr.b, X42/52/60/65/70/80 | Seamless steel pipe for line pipe |

| DIN 17175 | St35.8 | Seamless steel tube for elevated temperture |

| DIN 2391 | St35, St52 | Cold drawn seamless prevision pipe |

| DIN 1629 | St37.0, St44.0, St52.0 | Seamless circular unalloyed steel tubes subject to special requirements |

| GB/T 8162-2018 | 10, 20, 35, 45 | Structural Seamless Steel Pipes |

| GB/T 8163-2018 | 10, 20 | Fluid Transportation Seamless Steel Pipes |

| GB 3087-2008 | 10, 20, 20G | Medium & Low-Pressure Boiler Pipes |

| GB 5310-2017 | 20MnG, 25MnG | High-Pressure Boiler Pipes |

| GB 6479-2013 | 10, 20, 20G | High-Pressure Fertilizer Equipment Seamless Pipes |

| GB 9948-2013 | 10, 20 | Petroleum Cracking Seamless Pipes |

| GB/T 9711-2017 | L245 (Gr.b), L290 (X42), L360 (X52), L415 (X60), L450 (X65), L485 (X70), L555 (X80) | Oil & Gas Pipeline Pipes |

| GB/T 19830-2017 | H40, J55, K55, L80, N80, C95, P110, Q125 | Oil Casing & Tubing |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.