- 818-758-4076

- office@legit.com

- 3146 Koontz Lane, California

Product generic:

Casing and Tubing Coupling, Casing Coupling, Tubing Coupling

Application:

Used for connect two joints of tubing or casing

Specification:

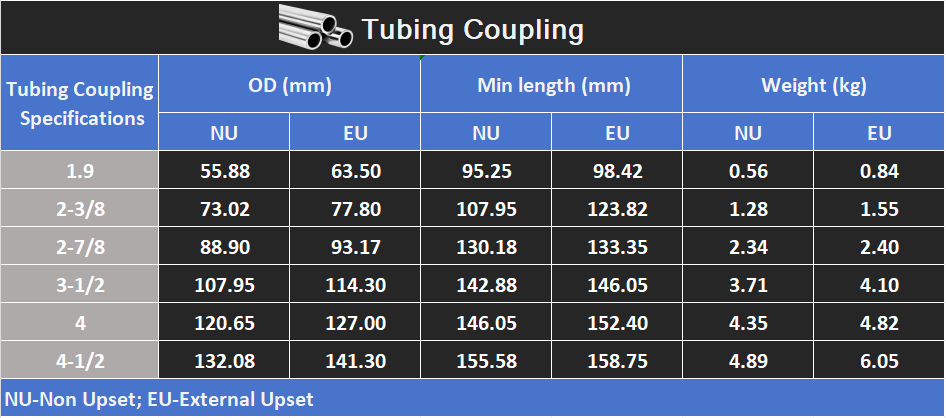

Tubing Coupling: 1.9”~ 4-1/2″

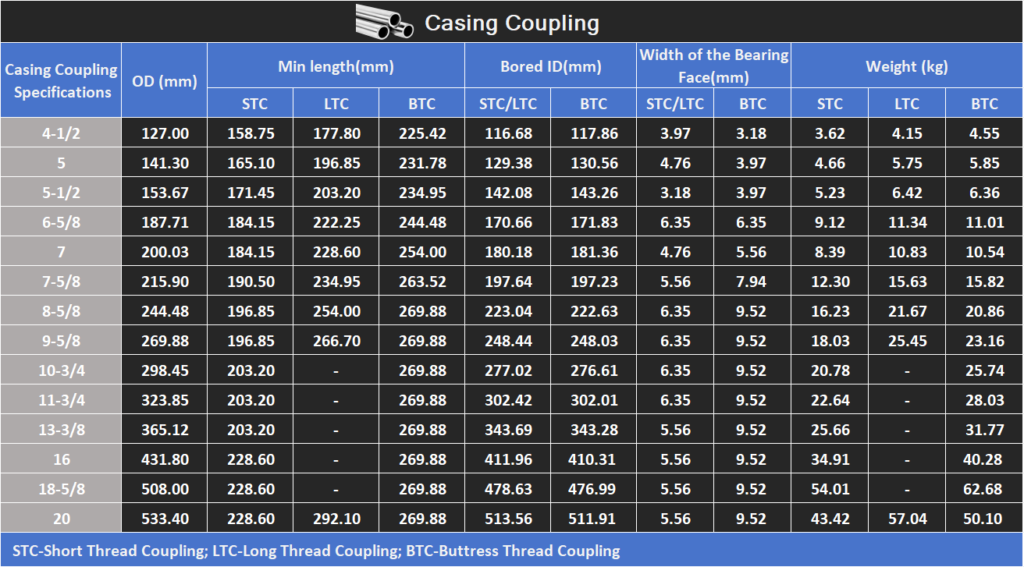

Casing Coupling: 4-1/2”~ 20”

Standard & Grade:

API 5CT and 5B :PSL1/PSL2 J55,K55,N80-1,N80-Q,L80-1, L80-9Cr,L80-13Cr,C90, C95, P110, Q125

Thread:

NUE, EUE, STC, LTC, BTC, HYDRILL CS,TENARIS XC,VAM

Surface:

Anti-corrosion&water Based Paint,Color codes painted which indicates different steel grades

A Coupling is a short connector used to join two pieces of OCTG (casing or tubing) by threaded connections, ensuring sealing integrity and mechanical strength.

Connection: Joins two pipes into a continuous string via threads. Sealing: Prevents leakage of downhole fluids (e.g., gas, crude oil). Load-bearing: Withstands tensile, compressive, and bending forces.

API 5CT, API 5B(American Petroleum Institute) ISO 11960 (International Organization for Standardization) GB/T 19830 (Chinese National Standard)

H40, J55, K55 : Standard wells (low corrosion) N80, L80, C90 : Medium-depth wells (moderate corrosion) P110, Q125 : Deep/ultra-deep wells (high collapse resistance) L80-13Cr : High CO₂/H₂S corrosive environments

Hot Rolling Cold Rolling Threading: API standard (NUE, EUE, STC, LTC, BTC) or premium connections (Hydril CS,Tenaris XC)

| Common standards for seamless carbon steel pipes | Common Grades | Application |

| ASTM A53 | Gr.A, Gr.B | Black and hot-dipped zinc-coated steel pipes welded and seamless |

| ASTM A106 | Gr.A, Gr.B, Gr.C | Seamless carbon steel for high temperature service |

| ASTM SA179 | SA179 | Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

| ASTM SA192 | SA192 | Seamless carbon steel boiler tubes for high pressure |

| ASTM SA210 | Gr.A1 | Seamless Medium-carbon boiler and superheater tubes |

| ASTM A333 | Gr.1(-50℃), Gr.6(-45℃,C-Mn) | seamless and welded carbon and alloy steel pipe intended for use at low temperatures. |

| ASTM SA519 | 1020 | Seamless carbon for mechanical tubing |

| API Spec 5CT | H40, J55, K55, L80, N80-1, C95, P110, Q125 | Seamless steel pipe for casing |

| API Spec 5L | PSL1/PSL2 Gr.a,Gr.b, X42/52/60/65/70/80 | Seamless steel pipe for line pipe |

| DIN 17175 | St35.8 | Seamless steel tube for elevated temperture |

| DIN 2391 | St35, St52 | Cold drawn seamless prevision pipe |

| DIN 1629 | St37.0, St44.0, St52.0 | Seamless circular unalloyed steel tubes subject to special requirements |

| GB/T 8162-2018 | 10, 20, 35, 45 | Structural Seamless Steel Pipes |

| GB/T 8163-2018 | 10, 20 | Fluid Transportation Seamless Steel Pipes |

| GB 3087-2008 | 10, 20, 20G | Medium & Low-Pressure Boiler Pipes |

| GB 5310-2017 | 20MnG, 25MnG | High-Pressure Boiler Pipes |

| GB 6479-2013 | 10, 20, 20G | High-Pressure Fertilizer Equipment Seamless Pipes |

| GB 9948-2013 | 10, 20 | Petroleum Cracking Seamless Pipes |

| GB/T 9711-2017 | L245 (Gr.b), L290 (X42), L360 (X52), L415 (X60), L450 (X65), L485 (X70), L555 (X80) | Oil & Gas Pipeline Pipes |

| GB/T 19830-2017 | H40, J55, K55, L80, N80, C95, P110, Q125 | Oil Casing & Tubing |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.