- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

Carbon/Alloy Steel Square & Rectangular Tubes,Square & Rectangular Steel Tubes,Custom Square & Rectangular Steel Tube

Application:

Building Structures,Bridges and Overpasses,Infrastructure Projects,Machinery Frames,Energy and Utilities,Architectural and Decorative Uses,Farm Equipment

Specification:

Cross-section: 10mm×10mm – 500mm×500mm

WT: 0.5~30mm

LENGTH: Fixed Length (5.8/6/11.8/12mtr),SRL, DRL

Standard & Grade:

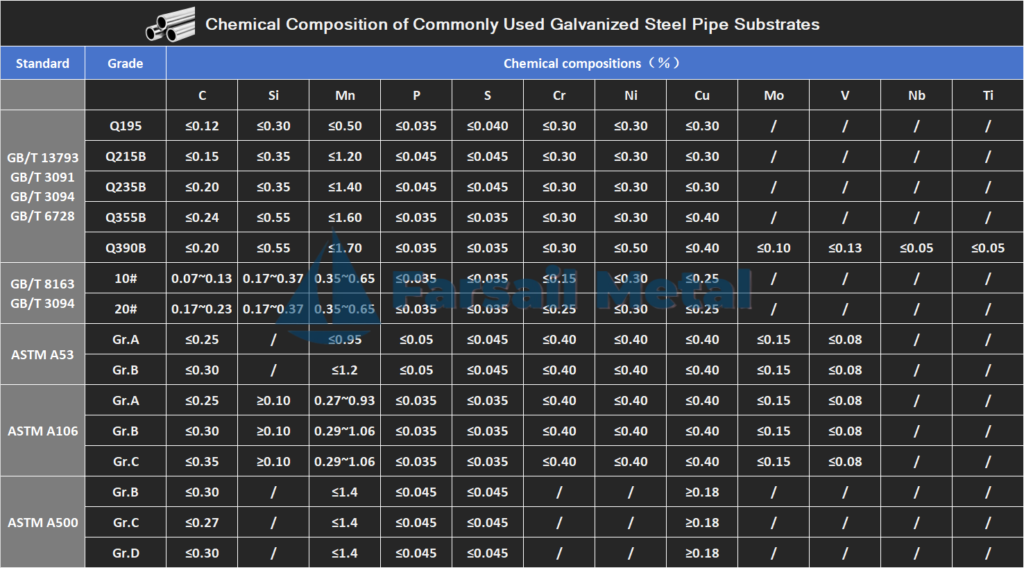

ASTM A53: Grade A、B,

ASTM A500: Grade B、C、D,

EN 10210-1: S235JR、S275J0H、S275J2H、S355J0H、S355J2H、S355K2H,

EN 10219:S235JRH、S275J0H、S275J2H、S355J0H、S355J2H、S355K2H;

GB/T 3094: 10#、20#、Q215A/B、Q235A/B、Q355B、Q390、Q420,

GB/T 6728: Q235B、Q355B、Q390、Q420;

Ends:

Plain Ends,Beveled Ends

Surface:

Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing:

Bundled/in Bulk, Plastic Caps Plugged,Waterproof Paper Wrapped

Common standards for Square, rectangular and special-shaped steel pipes | Common Grades | Main Application |

ASTM A500 | Gr.A, Gr.B, Gr.C | Cold-formed welded and seamless carbon steel structural tubing.(Building structures, bridges, mechanical frames, vehicle components, etc.) |

ASTM A513-18

| 1010, 1020, 4130 | Electric-resistance-welded carbon and alloy steel mechanical tubing.(Automotive drive shafts,gas springs,frames,Hydraulic cylinder barrels,etc.) |

EN 10219-1 | S235JRH, S355J2H, S460NH | Cold-formed welded structural hollow sections.(Industrial building frames,Offshore wind turbine towers, Highway crash barriers,Stadium trusses,Mobile crane booms,etc. ) |

EN 10210-1

| S275J2H, S460NH, S355NLH | Hot-finished structural hollow sections.( industrial building columns,bridge structures,Offshore oil platform jackets,Nuclear containment vessel supports,High-speed railway bridge piers,etc.) |

GB/T 6728-2017

| Q235, Q355, Q390 | Cold-formed hollow sections for structural use.(Building structures, mechanical manufacturing, bridge engineering, vehicle frames, etc.) |

GB/T 3094-2012

| 10#,20#,45#,Q345,304,316 | Cold-drawn special-shaped tubes .(Automotive drive shafts,Elevator guide rails,Medical device frames,Architectural decoration components, etc.) |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.