- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

Galvanized Square And Rectangular Tubes,Hot-Dip Galvanized Pipe,Zinc Coating Anti-Corrosive Steel Pipe

Application:

building frames, columns, and beams;handrails, guardrails, facades;traffic barriers, signpost frames, and street lamp poles;Bridges and Overpasses;frames for industrial machinery

Specification:

OD:10mm×10mm – 500mm×500mm

WT: 0.5~20mm

Zinc coating:250 g/m²(35μm)~1428 g/m²(200μm)

LENGTH: Fixed Length (5.8/6/11.8/12mtr),SRL, DRL

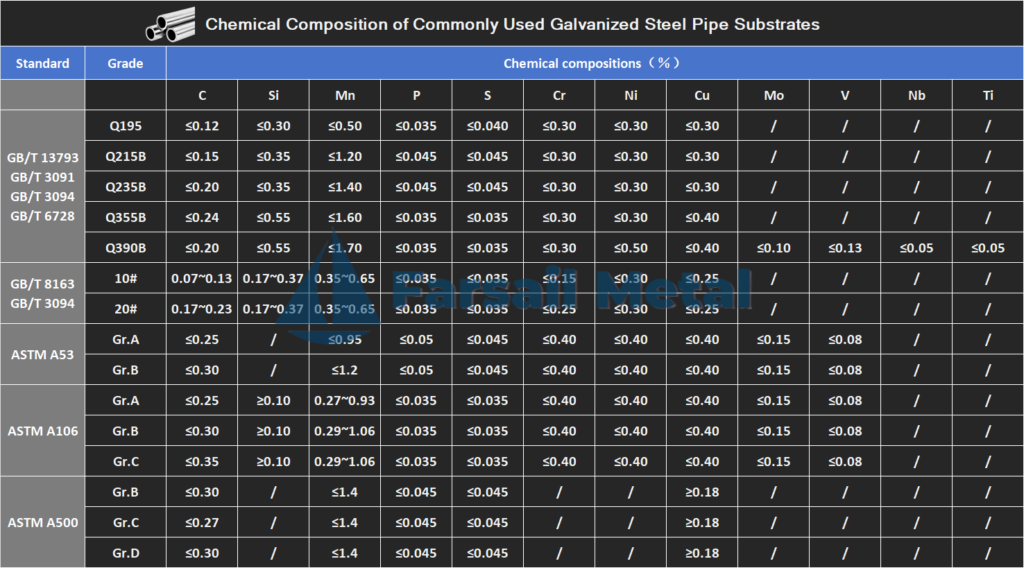

Standard & Grade:

ASTM A500: Grade B、C、D;

EN 10210-1: S235JR、S275J0H、S275J2H、S355J0H、S355J2H、S355K2H,

EN 10219:S235JRH、S275J0H、S275J2H、S355J0H、S355J2H、S355K2H;

GB/T 3094: 10#、20#、Q215A/B、Q235A/B、Q355B、Q390、Q420,

GB/T 6728: Q235B、Q355B、Q390、Q420;

Ends:

Plain Ends,Beveled Ends

Surface:

Zinc Coating

Packing:

Bundled/in Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Common standards for Galvanized steel pipes | Common Grades | Main Application |

ASTM A53 | Gr.A, Gr.B, Gr.C | Black and hot-dipped zinc-coated steel pipes welded and seamless.(Construction, machinery, pressure pipelines,etc.) |

EN 10240 | DC01,E235,E355 | nternal and/or external protective coatings for steel tubes—Specification for hot dip galvanized coatings.(Transportation of drinking water and gas) |

GB/T 3091 | Q195,Q215A,Q235A | Hot-Dip Galvanized Welded steel pipes for low-pressure fluid conveyance.(Transportation of low-pressure fluids such as water, gas, air, etc. ) |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.