- +86 192-8635-6263

- sale@farsailmetal.com

- No.6 Mudanjiang Road,Liaocheng,Shandong, China

- Sun - Fri (08AM - 10PM)

Product generic:

Spiral Welded Steel Pipe,Spiral Welded Pipe,Carbon Steel Spiral Welded Pipe,Large Diameter Spiral Welded Pipe

Application:

Municipal water supply and drainage,Low-pressure oil and gas transportation,Industrial fluid transportation,Piling and foundation engineering,Steel structure frames

Specification:

OD:168.3~3048mm

WT: 3~30mm

LENGTH: Fixed Length (5.8/6/11.8/12mtr),SRL, DRL

Standard & Grade:

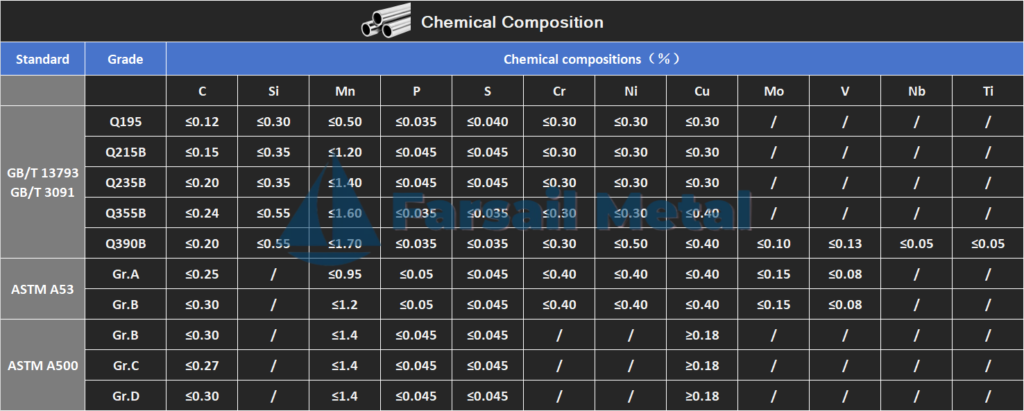

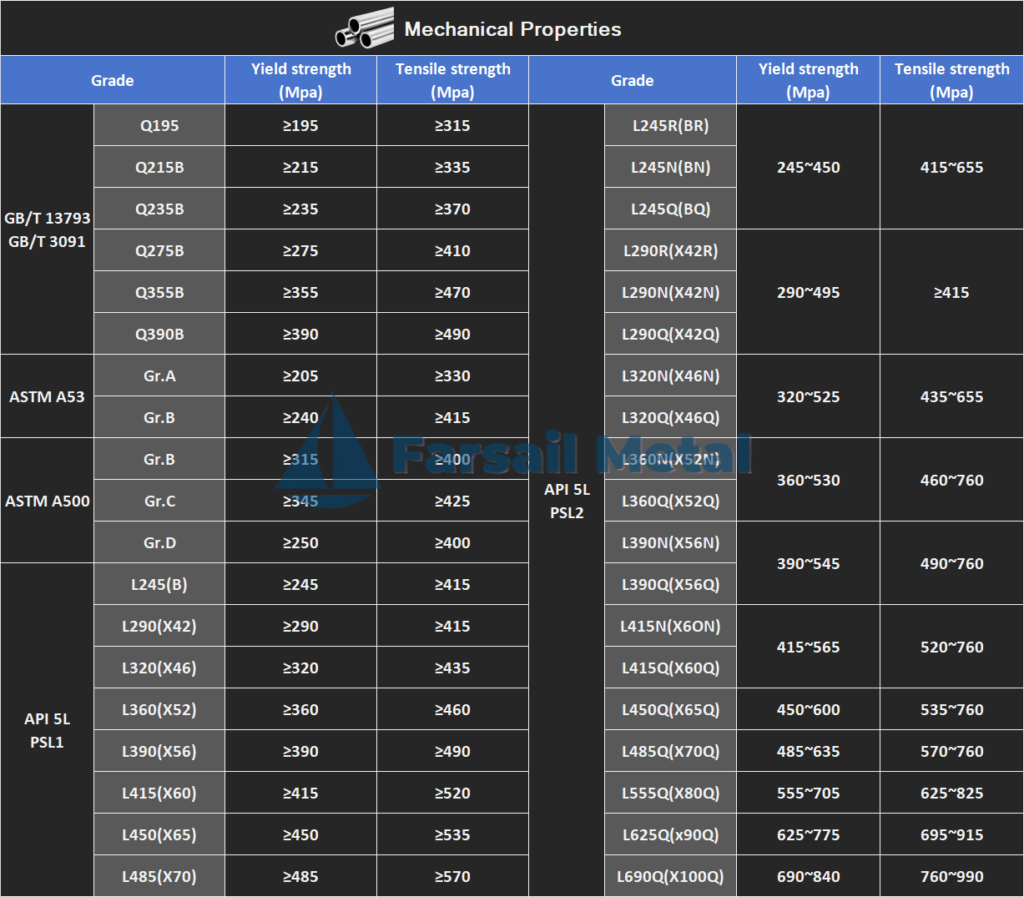

ASTM A53: Grade A、B,

ASTM A500: Grade B、C、D,

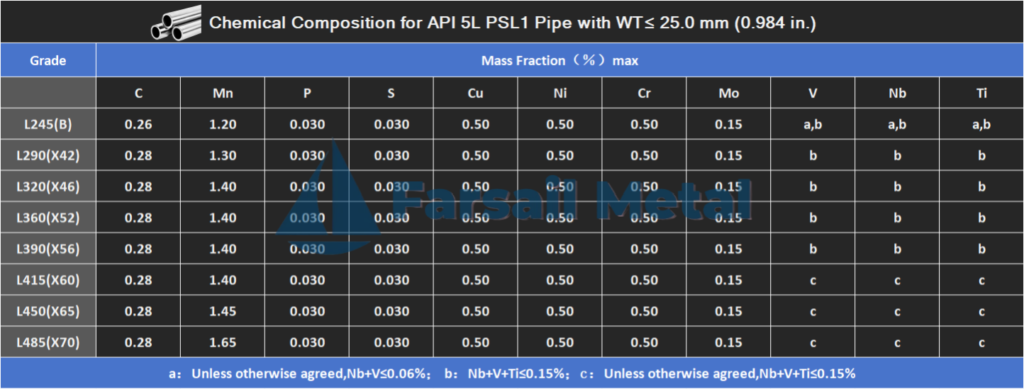

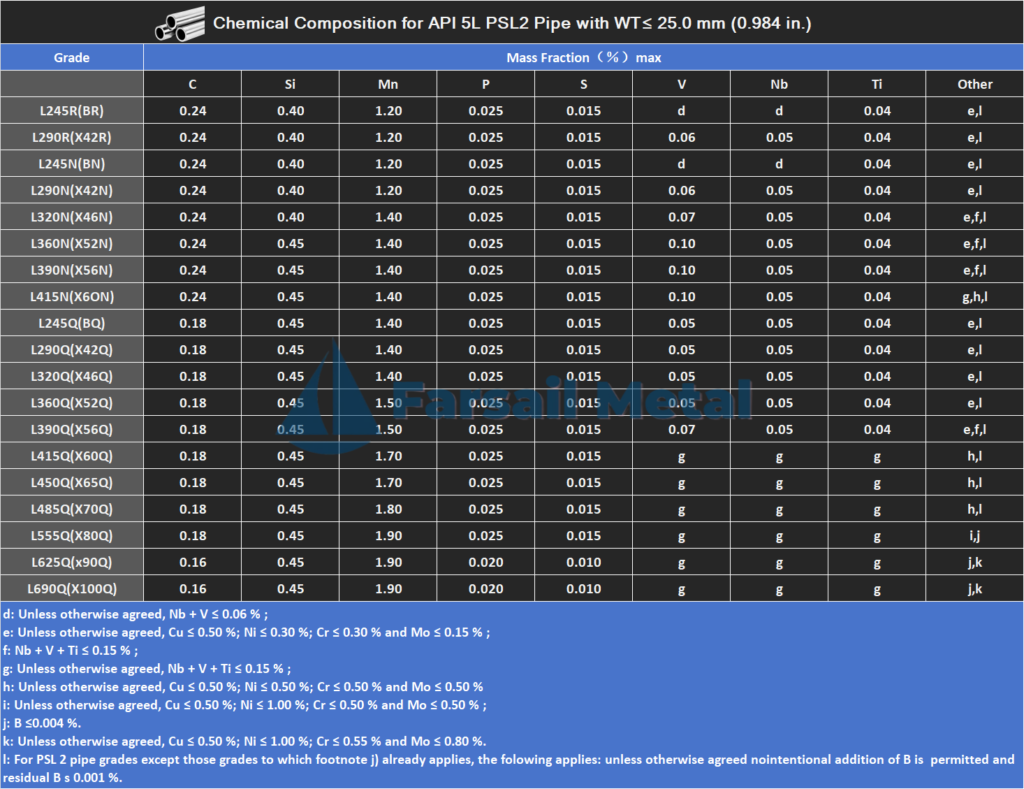

API 5L: L245(B),L290(X42),L320(X46),L360(X52),L390(X56),L415(X60);

EN 10217-1: P235GH、P355GH、P355NH,

EN 10219-1: S235JRH、S355NH、S355J2H;

GB/T 13793: Q195、Q215A/B、Q235A/B、Q355B、Q390B,

GB/T 3091: Q215A/B、Q235A/B、Q355B,

GB/T 9711: L245(B),L290(X42),L320(X46),L360(X52),L390(X56),L415(X60);

Ends:

Plain Ends,Beveled Ends,Threaded Ends

Surface:

Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Packing:

Bundled/in Bulk, Plastic Caps Plugged, Waterproof Paper Wrapped

Common standards for Welde carbon steel pipes | Common Grades | Main Application | |

Steel Pipe for Fluid Service | GB/T 14291 | Q195、Q215、Q235 | d pipe for mine fluid sevice |

GB/T 3091 | Q195、Q215、Q235 | Welded pipe for low pressure fluid service | |

SY/T 5037 | L245 (Gr.b), L290 (X42), L360 (X52), L415 (X60), L450 (X65), L485 (X70), L555 (X80) | Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service | |

ASTM A53 | Gr.A, Gr.B, Gr.C | Black and hot-hipped galvanized welded and seamless steel pipe | |

BS EN10217-1 | P195TR1,P235TR1 | Welded steel tubes for pressure purposes – Technical delivery conditions – Part 1: Electric welded and arc welded non-alloy steel tubes with specified room temperature properties | |

BS EN10217-2 | P265TR1,P295TR1 | Welded steel tubes for pressure purposes – Technical delivery conditions – Part 2: Electric welded and arc welded non-alloy steel tubes with specified elevated temperature properties | |

Steel Pipe for Ordinary Structure | GB/T 13793 | Q195、Q215、Q235、Q355B | Longitudinally electric resistance welded steel pipe |

SY/T 5040 | L245 (Gr.b), L290 (X42),L360 (X52), L415 (X60) | Spirally submerged arc welded steel pipe piles | |

ASTM A252 | Gr. 1,Gr. 2,Gr. 3 | Welded and seamless steel pipe piles | |

BS EN10219-1 | S235JRH,S355J2H,S460NH | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | |

Line Pipe | GB/T 9711.1 | (≈PSL1)L210(Gr.a),L245 (Gr.b), L290 (X42), L360 (X52), L415 (X60) | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

GB/T 9711.2 | (≈PSL2)L245NB,L415 N(X60), L450 N(X65), L485N (X70), L555N (X80) | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) | |

API 5L PSL1/2 | Gr.a,Gr.b, X42/52/60/65/70/80 | Line pipe | |

Casing | API 5CT/ ISO 11960 PSL1 | H40, J55,K55 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

©2024. Farsail Metal. All Rights Reserved.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.